Affordable and Eco-Friendly Transformer Maintenance With Regenerated Oil

The integration of regenerated oil in transformer maintenance provides an engaging method for companies looking for to boost both cost-efficiency and eco-friendliness. By utilizing oil that maintains performance requirements similar to virgin options, organizations can significantly reduce operational costs while at the same time lessening their ecological effect.

Comprehending Regenerated Oil

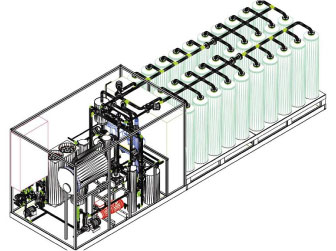

Regrowed oil, usually described as re-refined oil, is a critical component in the maintenance of transformers, providing both economic and ecological advantages. This oil is acquired from made use of mineral oils that have actually undertaken a thorough filtration procedure, successfully eliminating pollutants and bring back the oil to a quality comparable to virgin oil. The regeneration procedure commonly entails numerous phases, including physical separation, chemical therapy, and purification, making certain that pollutants such as sludge, water, and heavy metals are removed.

The application of restored oil in transformers is necessary for enhancing performance and expanding devices life expectancy. Top quality re-refined oil maintains its dielectric residential or commercial properties, ensuring reliable insulation and stopping electrical failures. Furthermore, it possesses superb thermal conductivity, which helps in handling the functional temperatures of transformers, ultimately boosting their reliability and performance.

Additionally, adopting restored oil not only sustains affordable maintenance methods but additionally minimizes the need for brand-new oil manufacturing, consequently conserving natural deposits. Transitioning to re-refined oil is a smart choice for companies aiming to preserve high functional requirements while simultaneously handling budget restrictions. Understanding the properties and advantages of restored oil is important for educated decision-making in transformer maintenance methods.

Ecological Benefits

The usage of regenerated oil in transformer maintenance supplies significant ecological advantages that add to sustainable methods within the power sector. Among the primary benefits is the decrease of waste oil disposal, as regenerated oil is stemmed from the recycling of utilized transformer oil, significantly lowering the volume of unsafe waste generated. This procedure helps reduce the ecological risks connected with incorrect disposal approaches, which can result in dirt and water contamination.

Additionally, the regeneration procedure conserves natural deposits by reducing the need for new base oil production - Transformer Oil Regeneration Plant. This conservation initiative not just reduces the extraction influence on ecological communities but also reduces the carbon footprint connected with oil production. By taking on restored oil, firms can further their commitment to environmental stewardship and align with global sustainability objectives

Furthermore, using restored oil enhances the overall performance of transformers, bring about minimized power losses and lower greenhouse gas exhausts. As the energy sector increasingly faces stress to lessen its ecological impact, embracing restored oil stands for a positive method to achieving both operational and ecological purposes. In summary, the environmental advantages of utilizing regenerated oil are multifaceted, advertising a much healthier planet while sustaining the power industry's change in the direction of sustainability.

Cost Savings and Performance

Using regenerated oil in transformer maintenance can bring about considerable cost financial savings and improved functional effectiveness for power business. Regenerated oil, generated with innovative filtration processes, Transformer Oil Regeneration Plant supplies equivalent performance to brand-new oil at a fraction of the cost. By recycling oil that would or else be disposed of, companies can reduce their buying expenses while decreasing garbage disposal costs.

Moreover, the extended life process of regrowed oil translates to reduced regularity of oil modifications, resulting in lower labor prices and decreased downtime for upkeep tasks. Transformer Oil Regeneration Plant. This not only improves operational effectiveness but also permits for a much more structured maintenance timetable, allowing companies to allot resources a lot more successfully

Furthermore, making use of regenerated oil can result in reduced insurance costs as a result of its eco-friendly profile. As energy companies deal with boosting analysis regarding their environmental effect, taking on sustainable practices such as using restored oil can reinforce their reputation and potentially draw in investment.

Ultimately, the combination of restored oil into transformer maintenance techniques offers a tactical possibility for energy firms to attain considerable price financial savings while promoting functional performance, therefore aligning monetary efficiency with ecological responsibility.

Comparison With Conventional Oils

While conventional oils have long been the requirement in transformer maintenance, a thorough comparison exposes that regenerated oils use a number of advantages that enhance performance and sustainability. Conventional mineral oils, while reliable, usually posture environmental risks, such as contamination and disposal issues. On the other hand, regenerated oils are stemmed from recycled materials, significantly reducing their eco-friendly impact.

They generally show premium oxidative stability, which translates to longer solution life and decreased frequency of oil modifications. This characteristic not only enhances transformer efficiency however additionally lessens downtime and maintenance costs.

In addition, regenerated oils give outstanding dielectric homes, making sure efficient electrical insulation. This top quality is critical in maintaining transformer performance under differing operational problems. Making use of regenerated oils likewise straightens with worldwide sustainability objectives, interesting organizations committed to reducing their carbon impact. Overall, the advantages of regenerated oils over traditional oils highlight their possible to revolutionize transformer maintenance methods, using an extra efficient and responsible option.

Application in Upkeep Practices

As soon as the analysis is total, a tailored prepare for transitioning to restored oil needs to be established, taking into consideration factors such as compatibility with existing products and functional conditions. Educating for upkeep workers is essential, as they have to recognize the one-of-a-kind properties of regenerated oils and just how to handle their application efficiently.

Applying an extensive surveillance program will facilitate the evaluation of efficiency metrics post-implementation, making sure the regenerated oil satisfies the called for operational requirements. Transformer Oil Regeneration Process. In addition, establishing a routine upkeep schedule will aid in identifying possible issues early and enable prompt restorative activities

Conclusion

In final thought, the fostering of regenerated oil for transformer maintenance offers a viable option that straightens economic benefits with ecological sustainability. By lowering costs associated with oil modifications and garbage disposal, while simultaneously prolonging the life expectancy of tools, companies can enhance operational effectiveness. The transition to regrowed oil not just minimizes environmental effects however likewise sustains more comprehensive sustainability objectives, making it a prudent choice for contemporary maintenance methods in the power field.

Restored oil, often referred to as re-refined oil, is a crucial element in the maintenance of transformers, offering both economic and environmental benefits. This oil is derived from used mineral oils that have undergone a comprehensive purification process, effectively removing contaminants and restoring the oil to a high quality comparable to virgin oil.Furthermore, taking on regenerated oil not just sustains cost-effective maintenance strategies but also reduces the need for brand-new oil manufacturing, consequently saving natural resources. One of the primary benefits is the decrease of waste oil disposal, as regenerated oil is obtained from the recycling of utilized transformer oil, considerably decreasing the volume of unsafe waste created. Restored oil, created through innovative filtration processes, supplies similar performance to brand-new oil at a fraction of the price.